|

But everything else is - foundations to finials, potting tray, guttering and coat rack.

..and this week I returned with the greenhouse and glass to finish the job.

I built the greenhouse from structural grade tanalised timber back in my workshop in Wales, including turning the finials on my lathe, building all the shelving, door, and windows. I then order up all the glass whilst painting the greenhouse and then load it all up in the van for the final visit.

Click below for a video tour of this week's build.

0 Comments

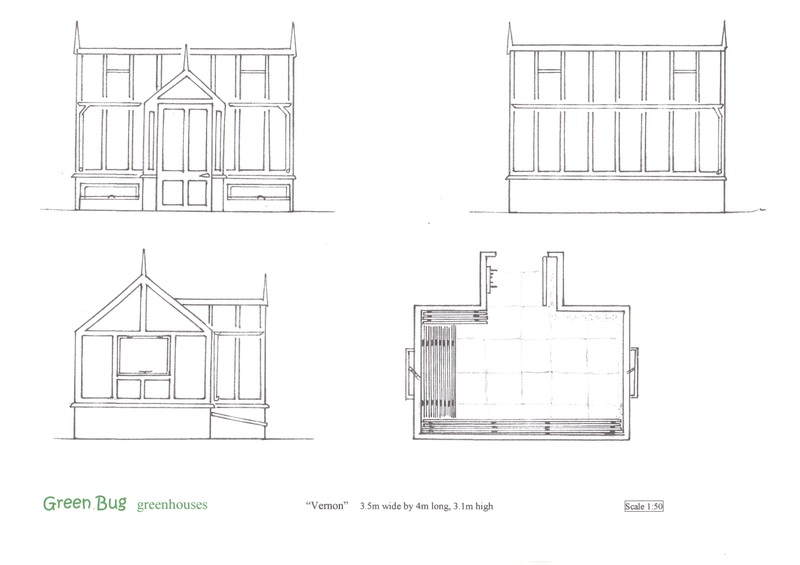

My customers want their greenhouse to completely fill an area between established borders. This greenhouse will be 3.3m wide by 5m long. It's going to look like it's been there forever. These kind folks must get the accolade of the most enthusiastic gardeners I have met - they grew over 150 tomato plants last year just for personal use and now want more space.

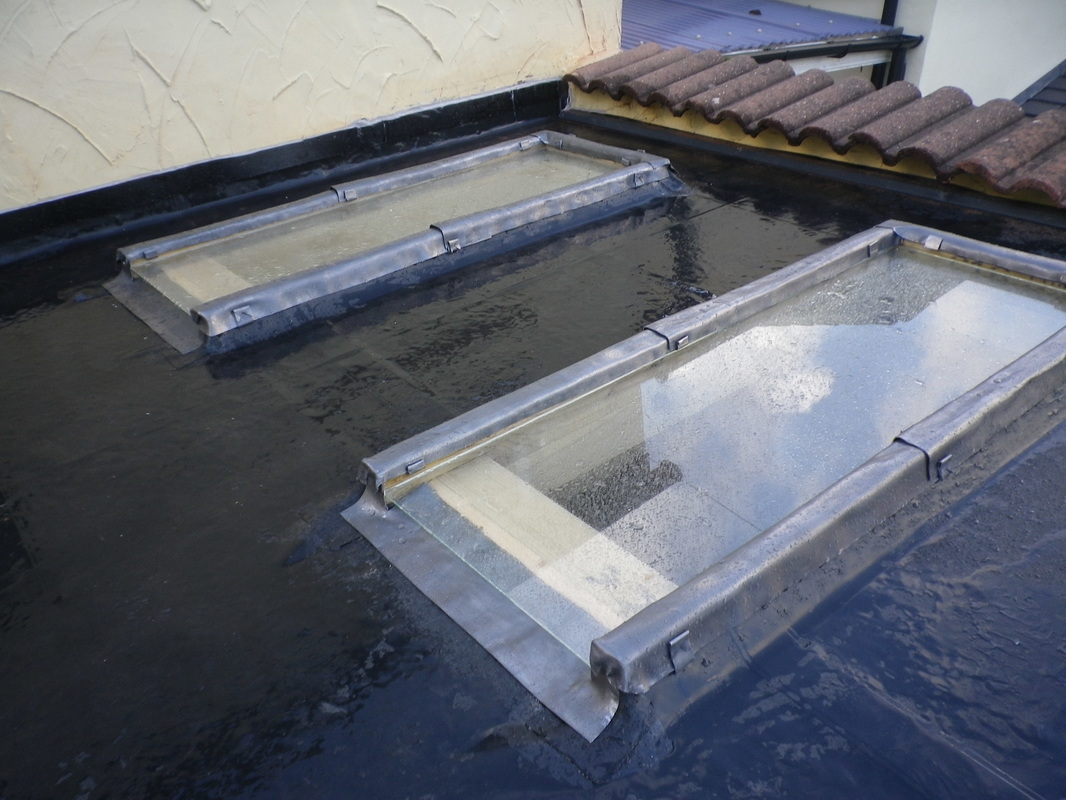

They asked me to leave the floor space as open earth until they get a feel how they want to use the greenhouse over the first year. It's a very large space with a lot of potential for growing direct into the ground. One small interesting addition is that I'll be fitting a flue for their wood-burning stove when I return in a few weeks. OK this isn't really a greenhouse I know but I built this as a favour for a mate and thought you should know what I've been up to. I was asked to build a new shed but thought it would be better to make the most of all the space available. I demolished all but part of the old lean-to, built and then rendered some new walls and made a new lean-to roof over the whole area. This shows the new walls after rendering and painting. I added two skylights with toughened glass and leaded around them and covered the roof with 18mm OSB and then covered it in EPDM flat roof covering.

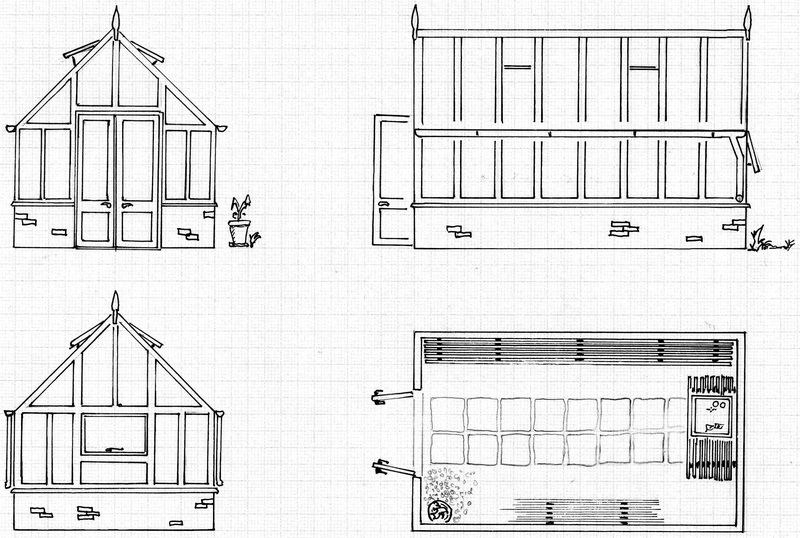

This one will be a 5m long "Vernon" to make the most of the available space.

The first job was to get rid of a few tonnes of loose top soil (thanks for the loan of the quadbike and trailer Paul) only to discover bedrock just below the surface - making the job of laying a strip trench foundation impossible.

However, with a 1-tonne of concrete mix anything is possible and stepped foundations were completed down the slope by second day.

I had to build a couple of small retaining walls along the front, filled with concrete, which were topped with facing bricks and filled with gravel to finish.

|

Click on each

|

RSS Feed

RSS Feed