|

My base build in Shropshire this week was just up the road from a greenhouse I had built 8 years ago - way back in June 2013. My previous customers had recommended me and asked that I call in to say hello when in the area. They still really loved and regularly used their greenhouse. I was keen to see how it looked. This is the orginal "Mike" greenhouse with brick floor and internal raised bed which you will find on the prices page. To read the blog entry from this build - click here to go to June 2013 in the archives.

0 Comments

The first thing that struck me was what a slope this is. You can see the gap between the front batten and the paint line on the ground and it tapers uphill a lot too. A huge amount of soil needed to be removed to get to a level point for the foundations. You can see how deep the foundations become as they go up the garden on the level - albeit with one step up along the way. The next job would be digging out all the internal soil so that I could start brick laying. This was a case of just get your head down and get on with it! I'd just started brick laying when I realised I would need to remove soil to the right hand side too. This is normally the place for a cold frame - not possible at this depth. What we would need is a retaining wall to hold all that bank of earth back from the greenhouse. Once I'd finished the greenhouse base I started on the retaining wall. I dug a trench and laid concrete blocks in a wet 3:1 mix of concrete. I cut reinforced steel bar and hammered then through the first blocks and into the wet concrete foundations and filled all the holes in the blocks, before laying the second course in mortar, fitting over the steel rods and again filling all holes with concrete to finish. The back can now be back filled with soil and a decorative facing course of bricks is going to be added by the customer at a later date. This is the base for a "Jill" greenhouse measuring 4m long by 2.8m wide with 5 side opening windows and 4 auto-opening roof windows built entirely in accoya. Now I've finished the base I can complete the front gable end back at the workshop and order up the glass before returning in a few weeks.

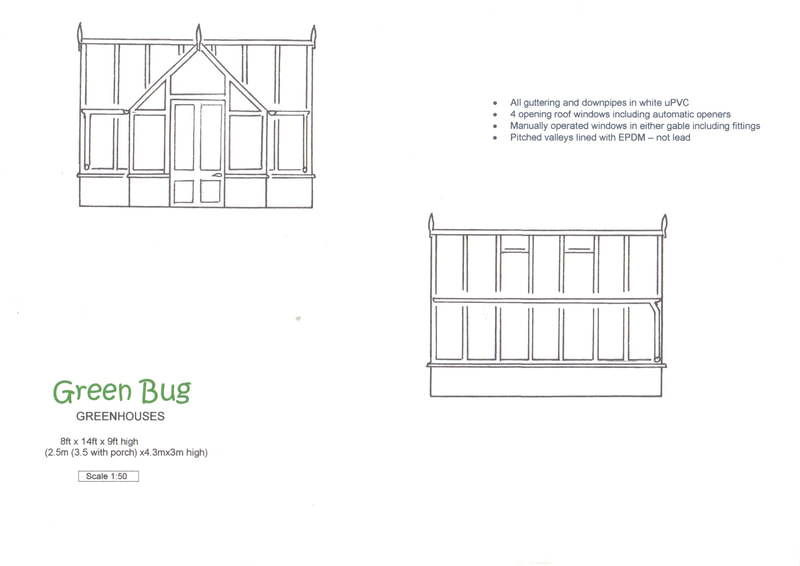

I've mocked up the top section of the "Miriam" greenhouse roof structure at the workshop so I could check the new valley angles. I decided to alter this greenhouse a little to make the glass panels slightly smaller. This does mean all the angles need changing but it's worth doing. I haven't built a "Miriam" for over 6 years and there are a few improvements I'm bringing into the design now.

This greenhouse will also be constructed entirely from accoya. The paint colour is green smoke (from the Farrow and Ball colour chart) which can look very dark on the chart but really works outside - looking much lighter in the photos below for instance.

After all that snow and stormy weather we had a week of great sunshine so I could complete this greenhouse. I made 3 visits here in all - the first to bed the wallplates down and take final measurements of the walls built by others, the next to erect the structure and check the valley glass dimensions. Once the valley glass arrived I made my final 3 day visit to complete. Most of the greenhouse was built and painted in my workshop before I made the first visit. The whole structure is made from accoya which carries a 50 year guarantee and will not warp, swell or shrink through the seasons- structurally stable and strong. Hi Robin,

Thank you so much for making the greenhouse, it's a dream come true and is a glasshouse, greenhouse, conservatory in one. I look forward to seeing your greenhouses on Instagram so please keep putting them on....I love a before and after story. Many thanks Nova and Andrew. X I turn all the finials by hand myself from stock timber. Did you know they are not just for decoration - they actually perform a really important function.... In high wind conditions/storms a blanket of wind will pass over the top of a building and cause negative air pressure below it – this pulls material out of roofs, and can lift sheds and greenhouses clear off their base. This is very unlikely to happen given the substantial base these greenhouses have. However, it is an extra worthwhile precaution. The finial works by breaking up that blanket of wind and prevent the wind uplift occurring.

You will see the similar function is provided by the small point of metal at the end of aircraft wings – preventing drag - a blanket of wind pulling the wing back. The finial needs to be high enough to stick a finger up into that wind blanket and break it apart. |

Click on each

|

RSS Feed

RSS Feed